Blog

26/08/2025

The Digital Transformation Imperative in Manufacturing: Why 85% of Manufacturers Believe It’s Essential

The manufacturing industry thrives on innovation, with digital technologies like 3D printing, cloud computing, and robotics shaping key processes and workflows. Embracing this new reality is no longer optional but a prerequisite for long-term success and survival.

According to Salesforce’s “Trends in Manufacturing” report, 85% of industry leaders believe they must transform their operations to remain competitive. This transformation journey offers unprecedented opportunities to drive growth across commercial operations, partner ecosystems, and service delivery, unlocking new revenue streams.

Such a transition requires more than just surface-level changes or tweaking old systems. Manufacturers must embrace digitalisation and reimagine how data flows, how systems interconnect, and how their businesses operate. At the same time, they must address the gaps in digital skills and empower employees to contribute to a culture of continuous innovation.

Digital transformation is a strategic imperative for manufacturers worldwide

The manufacturing world is moving at an unprecedented pace, and legacy systems aren’t cutting it anymore. Even with decades of operational excellence under their belts, many manufacturers are now seeing cracks in their foundations. The evidence is clear in performance metrics—on average, only about 40% of manufacturers are satisfied with their sales, marketing, service/aftermarket, and partner-channel operations.

According to Salesforce, 48% of manufacturing leaders believe their commercial operations require substantial changes, and 26% are planning a complete overhaul. Most respondents also expressed their intention to significantly revamp areas like service and aftermarket activities, as well as channel partnerships.

This shift in mindset points to something deeper: incremental improvements are no longer enough. To stay competitive, manufacturers need a fundamental transformation—one that connects systems, breaks down silos, and allows them to respond to market change in real time. That’s where digitalisation comes in.

For instance, IoT smart sensors allow manufacturers to monitor equipment performance in real time. These devices collect and analyse data on various parameters, then transmit it to centralised systems. Depending on how they are used, they can detect anomalies or potential failures, reduce downtime, improve production efficiency, and enhance safety.

Manufacturers can deploy this technology to improve their own operations or provide new digital services, such as predictive asset maintenance. It’s an opportunity to create value-added offerings and generate more revenue while deepening customer relationships.

Another example is artificial intelligence (AI), which plays a key role in product development, warehouse management, quality assurance, marketing, sales, and other operations. According to the World Economic Forum, some manufacturing companies that implemented AI reported a 30–40% boost in productivity, a 90% drop in downtime, a 25% reduction in maintenance costs, and a 16.7% improvement in warranty cost per unit.

These technologies often work together to create a more connected and agile ecosystem. By integrating them across every facet of operations, manufacturers can innovate faster, create better products, and drive revenue growth.

Key drivers of digital transformation in manufacturing

AI and other digital technologies have been used in manufacturing for years, but the need to adopt them is greater than ever. What’s changed is the urgency driven by factors like rising costs, growing competition, and shifting customer expectations.

According to 54% of the manufacturers surveyed by Salesforce, the increasing pressure on margins and profitability is a top driver for digital transformation. Other commonly cited factors include:

- The need for greater market agility (53%): Today’s market conditions change rapidly, forcing manufacturers to adapt with unprecedented speed to evolving customer demands, supply chain disruptions, and competitive threats.

- Emergence of new technologies and digital tools (49%): AI, IoT, smart manufacturing, and other technological advances offer powerful capabilities but also raise the risk of falling behind competitors who adopt them more effectively.

- Growing competition (48%): Digital-first enterprises are disrupting the manufacturing industry, positioning themselves as leaner, faster, and more customer-centric than their traditional counterparts. Additionally, global markets are becoming more accessible to newcomers, which further increases the competition.

- Changing customer expectations (45%): B2B buyers now expect the same personalised, seamless experiences they encounter as individual consumers, pushing manufacturers to rethink how they engage with customers.

Modern technology, a double-edged sword

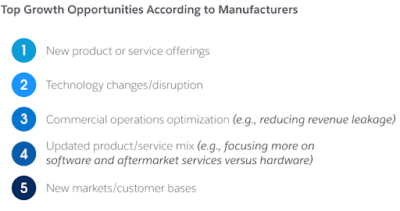

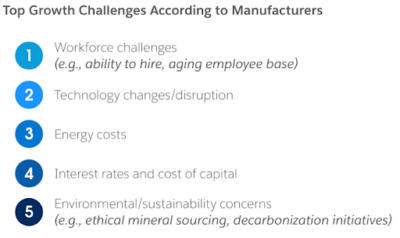

Perhaps the most fascinating insight from Salesforce’s report is that technology disruption ranks as both the second most significant growth opportunity and the second most pressing challenge for manufacturers.

On one hand, digital technologies deliver speed, visibility, and insights that legacy systems can’t match. On the other hand, their implementation can be complex and resource-intensive.

Take artificial intelligence, for instance. Per Salesforce, 80% of manufacturers have implemented or are experimenting with AI, but many are struggling to overcome hurdles like:

- Uncertainty about data security (39%)

- High implementation costs (38%)

- A lack of trust in AI-generated insights (36%)

- Difficulty integrating with existing systems (33%)

- Lack of internal expertise (32%)

These figures show that technology alone doesn’t drive transformation. Without a strong data foundation, a well-prepared workforce, and clear governance structures, even the most advanced tools will underperform. Or they won’t be used to their full potential, resulting in wasted resources.

Top investment priorities for manufacturers

Where are manufacturers placing their bets to address the challenges of digital transformation? Insights from the Salesforce survey highlight several strategic priorities:

- Technology investments lead the way: 68% of manufacturers expect to increase their technology budgets in the coming year, with similar increases planned for capital budgets (63%) and operational budgets (61%).A 2025 Deloitte survey reports similar findings, pointing to automation, data analytics, cloud computing, artificial intelligence, and other modern technologies as top investment priorities for manufacturers over the next two years.

- Sales and marketing initiatives are in the spotlight: The investments in these areas take precedence over those in product development, technology, manufacturing process efficiency, and supply chain optimisation. As margins tighten, manufacturers are realising they can’t afford inefficient go-to-market strategies.

- Product development and technology: Innovation remains high on the list, being a critical component of long-term success. Consumers have more options than ever, and their expectations are constantly evolving. To stay ahead, manufacturers must adapt to shifting market demands and continuously refine their products.

Despite these positive signals, the transformation journey remains challenging. Only 38% of manufacturers report exceeding their profitability targets, and similar gaps exist across other key performance indicators, such as customer satisfaction.

Industry leaders also show concern regarding unauthorised access, intellectual property theft, business disruption, and other issues. 65% of the manufacturers surveyed by Deloitte identified operational risk as one of their top challenges, followed by strategic (42%), cybersecurity (32%), financial (31%), and compliance (29%) risks.

Kick-start your digital transformation journey

Digital transformation isn’t a one-time initiative but an ongoing process that requires more than just new technology. Real impact comes from aligning digital tools and systems with business goals, organisational change, and process improvements.

While this process looks different for every manufacturing business, some core principles consistently drive success—like having a clear vision, aligning cross-functional teams, and building a strong technological foundation.

Here’s how to get it right:

1. Start with a clear vision

Successful transformation begins with a well-defined vision of what your manufacturing operations should look like in the future. This vision must align with your overall business strategy and specific outcomes, such as increased sales, lower defect rates, market expansion, or shorter production cycles.

Alternatively, start by looking at the challenges you face—and let them guide your digital transformation efforts. For instance, if you’re struggling with long lead times or unpredictable downtime, it may be worth exploring solutions like supply chain visibility platforms or predictive maintenance powered by IoT and machine learning.

2. Prioritise initiatives that address margin pressure

Focus on initiatives that directly impact the bottom line, helping maintain or improve profitability. These could include dynamic pricing models, supply chain automation, predictive maintenance, or other solutions aimed at reducing operational costs.

For example, integrating AI-powered analytics, IoT-enabled equipment tracking, and cloud-based ERP systems into your operations can enhance visibility across the value chain. With this approach, it’s easier to optimise resource allocation, adapt to market changes, and identify bottlenecks early on.

3. Build a strong technological foundation

According to Salesforce’s “Trends in Manufacturing” report, 85% of technical decision-makers say AI’s outputs are only as good as its data inputs. With that in mind, make sure you have the necessary data infrastructure in place prior to implementing advanced technologies like AI and machine learning.

An experienced Salesforce partner like Fludo can help you connect and optimise your data. After a thorough analysis, Fluido’s experts will set up and configure Salesforce Manufacturing Cloud to align with your business processes, laying the groundwork for AI-driven insights, automated workflows, and real-time performance tracking.

4. Don’t overlook people and processes

Technology alone isn’t enough to drive digital transformation. Manufacturers must also rethink their organisational structures, processes, and culture to fully reap the benefits.

If, say, you want to implement AI into production planning, don’t just focus on the tech—make sure your team is ready to use it effectively. This may require investing in upskilling or reskilling programs, providing continuous training, and building a culture of learning and innovation.

5. Address service and aftermarket operations

Service and aftermarket operations drive revenue, customer loyalty, and brand awareness. It’s an area you can’t afford to ignore or overlook.

One option is to leverage IoT-connected products and remote diagnostics to anticipate issues before they arise. Meanwhile, focus on developing new revenue streams from service offerings. For example, you could introduce subscription-based service contracts to generate recurring income and strengthen customer relationships.

The path forward for manufacturing businesses

The data is unequivocal: manufacturers face a transform-or-fall-behind reality. Those who successfully navigate this transition will likely emerge stronger, more agile, and better positioned to capture growth opportunities.

Again, digital transformation isn’t a one-time project but a continuous loop of learning, testing, and improving. Assess your current and future needs, identify the challenges that are holding you back, and then seek technology-driven solutions to address those pain points and carve the path forward. Be prepared to experiment, make mistakes, and learn with every step you take.

This journey won’t be easy or linear, but it’s necessary for manufacturing businesses that want not just to survive but to thrive. Let Fluido guide your efforts and help you maximise technology investments. Reach out to a consultant to discuss your needs and learn more about Salesforce Manufacturing Cloud.

Ilkka Donoghue

Director, Manufacturing Practice

Read next

28/08/2025